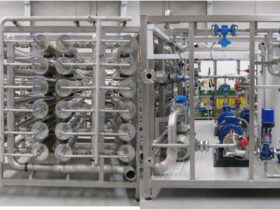

HNF – Compact nanofiltration plants

Nanofiltration

We design nanofiltration equipment using membranes to separate molecules with a high molecular weight, divalent ions and suspended material that makes effective quality improvements on applications where very low salinity is not required and yet offering lower energy consumption than reverse osmosis.

Therefore they are a highly competitive option for decalcifying hard water compared to traditional treatments using ionic exchange resins.

The nanofiltration process is very similar to reverse osmosis. The main difference revolves around the degree of retention achieved. The membranes operate in less selective ranges of molecular cut-off (between 0.001 – 0.01 micra).

They are used in demineralisation, for removing colour, organic matter and desalination. Also in concentrations of organic solutes, suspended solids and multi-purpose ions, the permeate contains monovalent ions and organic solutions for substances with a low molecular weight, such as alcohol.

Its main industrial applications are:

• Desalination of brackish waters with a significant bivalent salt content.

• Softening of water and reduction of sulphates, phosphates, ….

• Removing heavy metals.

• Reduction / removal of colour, organic matter and pesticides.

• Demineralisation of whey.

• Concentration of lactose and proteins.

• Reduction of acidity in wine.

• Filtering fruit juices.

• Concentration and separation of sugars.

• Recovery from CIP.

• Purification/Concentration of products.

• Recovery of subproducts (brine).

• Effluent treatment.

• Separation of substances with different molecular weight

HNF-AZ – Dextrose purification using nanofiltration

We use nanofiltration technology for dextrose purification, among other things, obtaining very high quality monosaccharides, separating them from disaccharides and other sugars with greater molecular weight.

The process is based on appropriate selection of the nanofiltration membrane. The fundamental difference lies in the possibility of filtering by molecule size, determining the molecular cut-off of its active surface area that in general, in this type of membrane can be between 150 and 3,000 dalton (unit of atomic mass). Working from this size, the membrane is used for ultrafiltration.

The membranes for this application are considered special both due to the molecular cut-off and due to their working conditions: extreme temperature and pressure and high levels of viscosity and suspended solids present in the fluids to be treated. Consequently, it is very important to select the membrane not only due to its molecular cut-off but also the shape and support materials used to manufacture it.

Hidrotec has developed technology to purify dextrose using nanofiltration giving high yield with highly optimised energy consumption.